PP, PE, ABS, PS, HDPE, PP thepa e pshatlehileng habeli ea mekhahlelo e 'meli ea ho sebelisoa hape le mochini oa granulation.

Parameter e kholo

Screw loader

● E lumellana le extruder feeding hopper ho hlokomela taolo ea othomathike.

Ea fepang

● Hopper thepa: tšepe e sa hloekang; Mokhoa oa ho fepa: Ho fepa ka li-screw; Feeder controller: E laoloa ke inverter.

Mochini oa Extruder

● Single screw extruder e nang le moea o phelisang hantle ho ntlafatsa boleng ba thepa. E na le moralo o khethehileng oa barrel le screw and single screw exhaust system, e ka netefatsa chai e ngata.

Sistimi ea ho qeta moea ka vacuum

● Ho ntša moea o sebetsang hantle ho ntlafatsa boleng ba thepa.

● Mokhoa o khathatsang: sefa metsi a vacuum.

● Kamore ea vacuum: moralo o khethehileng.

● Sekoahelo sa vacuum: motsoako oa aluminium.

● Vacuum tube: mocheso le khatello ea khatello ea methapo ea rabara.

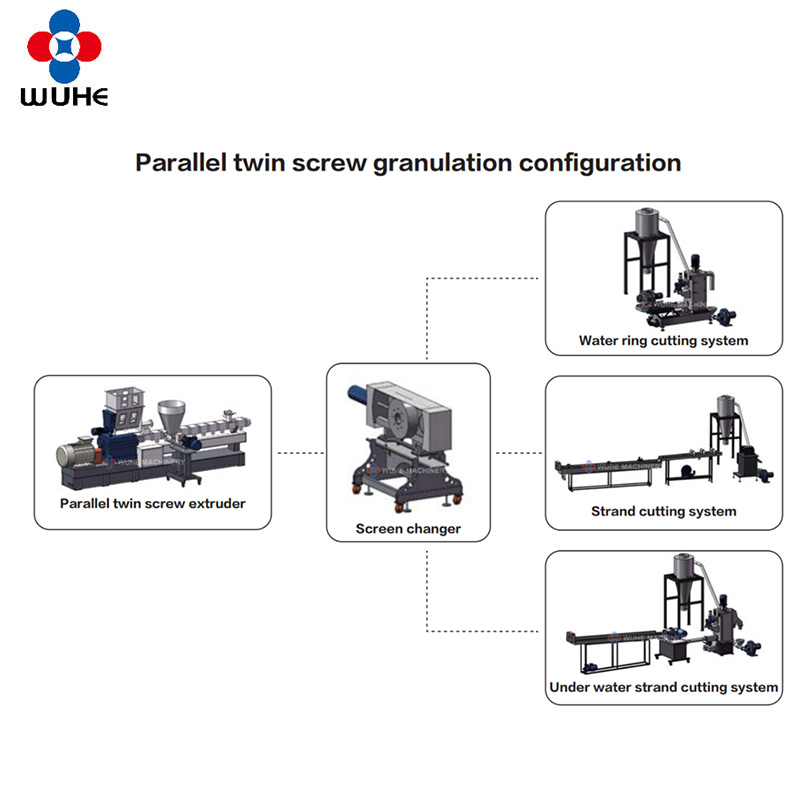

Granulation ea sethala se le seng le granulation ea sethala se habeli li khethoa ke thepa. Ka tlase ke lintlha tse qaqileng tsa extruder sethaleng sa bobeli.

Ngoana extruder

● Mehato e 'meli ea extruder e ka ntša metsi le litšila ka mokhoa o atlehang haholoanyane, 'me boleng ba likaroloana bo molemo.

Ho fetola skrine

● Liphetoho tse fapaneng tsa skrine li finyella litlhoko tsa bareki ba fapaneng.

Haholo-holo re na le mekhoa e meraro ea tsamaiso ea ho khaola li-pellets:

1. Mokhoa oa ho itšeha lesale la metsi.

2. The strand cutting system.

3. Mokhoa oa ho itšeha ka tlas'a metsi.

Ho itšetlehile ka litšobotsi tse fapaneng tsa thepa, re tla khothaletsa mekhoa e fapaneng ea ho itšeha.

1. Mokhoa oa ho itšeha oa metsi

● Tsamaiso ea ho itšeha e amohela lesale la metsi a extrusion shoela ho khaola, e ka netefatsang ponahalo e phethahetseng ea karoloana.

Mochine o hlatsoang metsi oa centrifugal

● Mochine ona o na le melemo e mengata, e kang tekanyo e phahameng ea ho felloa ke metsi 'meleng, tšebeliso e tlaase ea matla, bokhoni bo phahameng, tekanyo e phahameng ea ho iketsetsa,' me e fokotsa haholo matla a mosebetsi. Dehydration e hloekile, 'me e ka boela ea hlatsoa lehlabathe le lenyenyane le li-sundries tse nyane ka har'a pla.

2. Strand cutting system

● Bakeng sa lisebelisoa tse ling tse nang le viscosity e phahameng, tse kang PP, re khothalletsa ho sebelisa mokhoa oa ho itšeha.

3. Tsamaiso ea ho itšeha ka tlas'a metsi

● E loketse lisebelisoa tse phahameng tse qhibilihisang, tse kang PET le PP joalo-joalo.

● Ho omisa lipeipi tsa moea

Metsi a ka holim'a li-pellets a fetoha mouoane ka mokhoa oa phepelo ea moea, 'me a isa li-pellets tse omisitsoeng ho sekoti sa pokello, ebe bakeng sa kalafo e latelang.

Sistimi ea taolo ea motlakase

● PLC ea ho laola ka mokhoa o itekanetseng

Setšoantšo sa lintho tse bonahalang