Mochini oa Polasetiki oa ho Recycling Granulation ke mofuta oa lisebelisoa tse sebelisetsoang ho sebetsa litšila kapa ho lahla polasetiki ka har'a granule ea polasetiki e ka sebelisoang hape. E qhibilihisa thepa ea polasetiki e sebelisitsoeng joalo ka PE, PP, kapa PET ebe e li hlophisa bocha hore e be li-pellets tse nyane, tse ts'oanang ka extrusion le ho itšeha.

Mochini ona o bapala karolo ea bohlokoa molemong oa ho sebelisa polasetiki hape ka ho fetola lipolasetiki tse lahliloeng hore e be thepa e tala bakeng sa lihlahisoa tse ncha. E thusa ho fokotsa tšilafalo ea polasetiki, e theola litšenyehelo tsa tlhahiso, 'me e tšehetsa tlhahiso e tsitsitseng ho pholletsa le liindasteri tse kang ho paka, ho haha le thepa ea bareki.

Ho utloisisa likarolo, melemo le mathata, le ts'ebeliso e ka bang teng ea Mochini oa Polasetiki oa ho Recycling Granulation ho tla u thusa ho etsa liqeto tse betere le ho khetha granulator e nepahetseng kapa motsoako ho fihlela litlhoko tsa hau tsa tlhahiso.

Tsoela pele ho bala ha re ntse re qaqisa Mechini e mengata e fapaneng ea Polasetiki ea ho Recycling Granulation le ho fana ka tataiso e khutšoane qetellong ea sengoloa ho khetha granulator e ntle ka ho fetisisa bakeng sa projeke ea hau.

Mefuta eaMochini oa Granulation oa Plastic Recycling

Mechini ea Sejoale-joale ea Polastiki ea ho Recycling Granulation e entsoe ka litsamaiso tse baballang matla, taolo ea mocheso o ikemetseng, le tlhoekiso e tsoetseng pele ho netefatsa li-granules tsa boleng bo holimo. Li sebelisoa haholo limela tsa ho tsosolosa, lifeme tsa lihlahisoa tsa polasetiki, le litsi tsa ts'ebetso ea tikoloho ho sebetsana le litšila tse ngata tsa polasetiki, ho tloha filiming le libotlolong ho ea likarolong tse entsoeng ka ente.

Ka mor'a moo, re tla tšohla ka bokhutšoanyane mefuta e 12 e fapaneng ea li-granulator.

1. Recycling compactor granulation line

A Recycling Compactor Granulation Line ke mokhoa o felletseng o sebelisetsoang ho sebetsa litšila tsa polasetiki tse bobebe-joaloka lifilimi, mekotla e lohiloeng le thepa e phophomang—ho etsa li-pellets tse teteaneng tsa polasetiki. E kopanya compaction, extrusion, filtration, le pelletizing ts'ebetsong e le 'ngoe e tsoelang pele. The compactor pre-compresses soft or bulky materials, e etsa hore ho be bonolo ho fepa ka har'a extruder ntle le ho koala kapa ho koala.

Melemo

Phepo e Sebetsang: Thepa e hahelletsoeng ka har'a komporo ea pele e sebetsana le lisebelisoa tse bobebe le tse fluffy, e thibelang ho thibela phepelo.

Sistimi e Kopanetsoeng: E kopanya compaction, extrusion, filtration, le pelletizing moleng o le mong o tsoelang pele.

Ho Boloka Sebaka le Mosebetsi: Moralo o kopaneng o nang le boiketsetso bo phahameng o fokotsa tlhoko ea mosebetsi oa matsoho le sebaka sa feme.

Tšebelisano e Pharalletseng: E sebetsana le lipolasetiki tse fapaneng tse bonolo joalo ka filimi ea PE / PP, mekotla e lohiloeng le lisebelisoa tsa foam.

Boleng bo tsitsitseng ba Pellet: E hlahisa li-granules tsa polasetiki tse tšoanang tse loketseng ho sebelisoa hape tlhahiso.

Mefokolo

Ha e Lokele Lipolasetiki tse Thata: Lipolasetiki tse teteaneng kapa tse thata (mohlala, likarolo tse entsoeng ka ente, libotlolo) li ka hloka mechine e meng.

Bohloeki ba Lintho bo Hlokehang: Boemo bo phahameng ba mongobo kapa tšilafalo (joaloka litšila kapa pampiri) bo ka ama ts'ebetso le boleng ba pellet.

Tlhokomelo ea Kamehla e Hlokahala: Libaka tsa compactor le filtration li hloka ho hloekisoa nako le nako ho netefatsa ts'ebetso e tsitsitseng.

Lisebelisoa

Agricultural Film Recycling: Bakeng sa filimi ea PE mulch, filimi ea greenhouse, le lipolasetiki tse ling tsa mapolasi.

Packaging ea Post-Consumer Plastic: E loketse ho sebetsana le mekotla ea mabenkele, filimi e otlolohileng, mekotla ea li-courier, joalo-joalo.

Pholiso ea Matla a Liindasteri: E tsosolosa litšila tsa tlhahiso ho tsoa ho baetsi ba lifilimi le mekotla e lohiloeng.

Lits'oants'o tsa Plastiki tsa ho Hlakola: Li loketse hantle bakeng sa meaho e sebetsanang le litšila tse ngata tse bonolo tsa polasetiki.

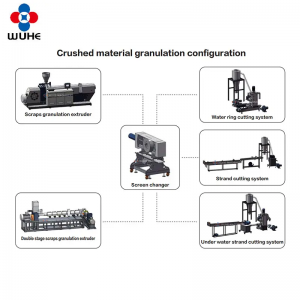

2.Mohala oa granulation oa thepa e sithabetseng

A Crushed Material Granulation Line ke mokhoa oa ho sebelisa hape polasetiki o etselitsoeng ho sebetsana le litšila tsa polasetiki tse thata tse seng li khahliloe kapa li pshatliloe hore e be li-flakes. Sena se kenyelletsa lisebelisoa tse kang HDPE, PP, PET, ABS, kapa PC ho tsoa libotlolong, lijana le likhechana tsa indasteri. Hangata mohala o kenyelletsa tsamaiso ea ho fepa, e le 'ngoe kapa mafahla-screw extruder, filtration unit, pelletizing system, le karolo ea ho pholisa / ho omisa.

Melemo

Ho fepa ka ho Otloloha ha Lintho Tse Senyehileng: Ha ho tlhokahalo ea pele ho compaction; e loketse lipolasetiki tse thata joalo ka libotlolo, lijana, le likarolo tsa ente.

Output e tsitsitseng: E sebetsa hantle ka thepa e ts'oanang, e teteaneng, e fana ka extrusion e tsitsitseng le boleng ba pellet.

Sebetsa se Phahameng: Moralo o matla oa li-screw le sistimi e sebetsang ea degassing e ntlafatsa ho qhibiliha le ho fokotsa litaba tsa mongobo.

Flexible Configuration: E ka ba le lisebelisoa tse nang le li-extruder tsa mekhahlelo e le 'ngoe kapa tse peli, li-ring-ring kapa li-pelletizer tsa strand tse thehiloeng ho mofuta oa thepa.

E ntle bakeng sa Regrind e Hloekileng: E sebetsa haholo ha o lokisa liphaephe tsa polasetiki tse hloekileng, tse hlophiloeng ho tloha mehalang ea ho hlatsoa.

Mefokolo

Ha e Loke bakeng sa Plastiki e Bonolo kapa e Fluffy: Lisebelisoa tse bobebe joalo ka lifilimi kapa foam li ka baka ho se tsitse ha phepo kapa borokho.

E hloka ho hlatsuoa pele: Lisebelisoa tse silafetseng kapa tse silafetseng li hloka ho hloekisoa hantle pele ho granulation.

Ha e Tšoanelehe Bakeng sa Li-Plasitiki Tse Kopantsoeng: Ho lumellana ha thepa ho ama boleng ba pellet; mefuta e tsoakiloeng ea polymer e ka hloka ho tsoakoa kapa ho arohana.

Lisebelisoa

Recycling ea polasetiki e thata: Bakeng sa libotlolo tsa HDPE/PP, lijana tsa shampoo, libarele tsa sesepa, jj.

Post-Industrial Plastic Scrap: E loketse masala a pshatlehileng a tsoang ho ente, extrusion, kapa blowing.

Li-Flakes tse hlatsoitsoeng tse tsoang ho Recycling Lines: E sebetsa hantle ka li-flakes tse hloekisitsoeng tsa PET, PE, kapa PP tse tsoang lits'ebetsong tsa ho hlatsoa libotlolo.

Bahlahisi ba Pellet ea Plastiki: E loketse baetsi ba fetolang regrind e hloekileng hore e be li-pellets tse ka sebelisoang hape bakeng sa ente kapa extrusion.

3. Lohiloeng lesela mokotla recycling pelletizing line

A Woven Fabric Bag Recycling Pelletizing Line ke sistimi e ikhethileng ea ho e sebelisa hape e etselitsoeng ho sebetsana le mekotla e lohiloeng ea PP (polypropylene), raffia, jumbo bags (FIBCs), le masela a mang a polasetiki a tšoanang. Lisebelisoa tsena hangata li bobebe, ha li na meokho, 'me ho thata ho li fepa ka kotloloho lits'ebetsong tsa setso tsa pelletizing ka lebaka la sebopeho sa tsona se seholo. Mohala ona o kopanya ho pshatla, ho kopanya, extrusion, filtration, le pelletizing hore e be mokhoa o tsoelang pele o fetolang lisebelisoa tsa polasetiki tse lohiloeng hore e be li-pellets tsa polasetiki tse tšoanang.

Tharollo ena e loketse bakeng sa ho tsosolosa litšila tse entsoeng ka mor'a indasteri le ka morao ho bareki, ho thusa ho fokotsa tšilafalo ea tikoloho le ho nchafatsa thepa e tala bakeng sa indasteri ea polasetiki.

Melemo

Sistimi e Kopanetsoeng ea Compactor: E hatella lisebelisoa tse bobebe, tse lohiloeng ho netefatsa phepo e boreleli le e tsitsitseng ka har'a extruder.

Sebetsa se Phahameng: E etselitsoe ts'ebetso ea maemo a holimo ka ts'ebetso e tsoelang pele le litlhoko tse tlase tsa basebetsi.

Sehlahisoa se tšoarellang le se tsitsitseng: E hlahisa li-pellets tse tšoanang tse nang le lisebelisoa tse ntle tsa mochini, tse loketseng ho sebelisoa hape ka tlase ho noka.

E sebetsana le lisebelisoa tse thata: E etselitsoe ho sebetsana le mekotla e lohiloeng, mekotla ea jumbo e nang le liner, le litšila tsa raffia.

Moralo o Customizable: E ka hlophisoa ka mekhoa e fapaneng ea ho itšeha, ea ho senya le ea ho hloekisa e etselitsoeng maemo a fapaneng a thepa.

Mefokolo

Hangata ho Hlokahala Phekolo ea Pele: Mekotla e lohiloeng e litšila e ka hloka ho hlatsuoa le ho omisoa pele e sebelisoa hape ho boloka boleng ba pellet.

Tšebeliso e Phahameng ea Matla: Ka lebaka la ho kopana le ho qhibiliha ha thepa e teteaneng, tsamaiso e ka sebelisa matla a mangata.

Sensitivity ea Material: Botenya ba thepa bo sa tsitsang kapa likhoele tse setseng tsa ho roka li ka ama phepelo le botsitso ba extrusion.

Lisebelisoa

Recycling PP Woven Sacks: E loketse mekotla ea samente, mekotla ea raese, mekotla ea tsoekere, le mekotla ea lijo tsa liphoofolo.

Jumbo Bag (FIBC) Reprocessing: Tharollo e Sebetsang bakeng sa ho sebelisa hape lijana tse kholo tse tenyetsehang tsa lipakeng tse ngata.

Recycling ea Litšila tsa Textile le Raffia: E loketse baetsi ba masela a lohiloeng le lihlahisoa tsa raffia hore ba boele ba sebelise sekoaelo le maqhetsoana.

Tlhahiso ea Pellet ea Plastiki: E hlahisa li-granules tsa PP tsa boleng bo holimo bakeng sa ho sebelisoa hape ho bopeng ente, extrusion, kapa ho foka filimi.

4.EPS / XPS Granulation Line

EPS/XPS Granulation Line ke mokhoa o ikhethileng oa ho sebelisoa hape o etselitsoeng ho sebetsa polystyrene e atolositsoeng (EPS) le litšila tse tlositsoeng tsa polystyrene (XPS) ka har'a granule tsa polasetiki tse ka sebelisoang hape. EPS le XPS ke lisebelisoa tse bobebe, tse phophomang tse atisang ho sebelisoa ho paka, ho kenya letsoho le ho haha. Ka lebaka la sebopeho sa tsona se seholo le sets'oants'o se tlase, ho thata ho sebetsana le lisebelisoa tse tloaelehileng tsa polasetiki. Mohala ona oa granulation hangata o kenyelletsa ho pshatla, ho kopanya (ho qhibiliha kapa ho tiisa), extrusion, filtration, le pelletizing systems.

Sepheo se seholo sa mohala ona ke ho fokotsa molumo, ho qhibiliha, le ho tsosolosa litšila tsa EPS / XPS tsa foam ho li-pellets tsa polystyrene (GPPS kapa HIPS), tse ka sebelisoang hape ho etsa polasetiki.

Melemo

Phokotso ea Bolulo: Sistimi ea komporo kapa ea densifier e fokotsa haholo boholo ba lisebelisoa tsa foam, e ntlafatsa ts'ebetso ea phepelo.

Sehlahisoa se Phahameng se nang le Lisebelisoa tsa Leseli: E etselitsoe ka ho khetheha bakeng sa foam e tlaase-tlaase, e netefatsang phepo e tsitsitseng le extrusion e tsoelang pele.

Moralo oa Screw O bolokang Matla: Sekoaelo se ntlafalitsoeng le sebopeho sa moqomo se netefatsa ho qhibiliha hantle ka tšebeliso e fokotsehileng ea matla.

E Setsoalle le Tikoloho: E thusa ho fokotsa litšila tsa litšila le ho ts'ehetsa ts'ebeliso e chitja ea liphutheloana tsa foam le lisebelisoa tsa ho kenya letsoho.

Sephetho se Recyclable: Li-granules tse hlahisoang li loketse ho sebelisoa hape lits'ebetsong tseo e seng tsa lijo joalo ka maqephe a insulation kapa profaele ea polasetiki.

Mefokolo

E Hloka Foam e Hloekileng le e Omileng: EPS / XPS e tlameha ho se be le oli, lijo, kapa tšilafalo e boima ho boloka boleng ba pellet.

Ho Hlokahala Taolo ea Monko le Mosi: Foam e qhibilihang e ka ntša mosi; tsamaiso e nepahetseng ea moea kapa ea ho ntša metsi e bohlokoa.

Ha e Lokele Li-Plasitiki Tse Kopantsoeng: Tsamaiso e ntlafalitsoe bakeng sa EPS / XPS e hloekileng; lisebelisoa tse tsoakiloeng li ka koala kapa tsa theola boleng ba tlhahiso.

Lisebelisoa

Packaging Foam Recycling: E nepahetse bakeng sa ho sebelisa liphutheloana tse tšoeu tsa EPS tse sebelisoang ho lisebelisoa tsa elektroniki, lisebelisoa le thepa ea ka tlung.

Tsoelo-pele ea Lisebelisoa tsa Kaho: E loketse bakeng sa sekhechana sa boto ea XPS ho tloha ho insulation ea moaho le liphanele tsa marako.

Taolo ea Litšila tsa Feme ea Foam: E sebelisoa ke baetsi ba lihlahisoa tsa EPS/XPS ho sebelisa likotoana tse hanngoeng hape.

Tlhahiso ea Pellet ea Polystyrene: E fetolela litšila tsa foam hore e be li-granules tsa GPPS/HIPS bakeng sa lits'ebetso tse tlase tse kang lilakane tsa polasetiki, li-hangers kapa lihlahisoa tse bōpiloeng.

5. Parallel Twin Screw Granulation Line

Parallel Twin Screw Granulation Line ke sesebelisoa sa polasetiki se sebelisang li-screw tse peli tse bapileng ho qhibilihisa, ho kopanya le ho peta lisebelisoa tse fapaneng tsa polasetiki. Ha ho bapisoa le li-scruders tse le 'ngoe, li-screws tse peli li fana ka motsoako o betere, tlhahiso e phahameng, le taolo e kholo holim'a maemo a ts'ebetso. Sistimi ena e loketse ka ho khetheha bakeng sa ho nchafatsa lipolasetiki tse tsoakiloeng, ho kopanya li-additives, le ho hlahisa li-granules tsa polasetiki tsa boleng bo holimo tse nang le thepa e ntlafalitsoeng.

Mohala ka kakaretso o na le sistimi ea ho fepa, parallel twin screw extruder, filtration unit, pelletizer, le karolo ea ho pholisa/ho omisa, e etselitsoeng ts'ebetso e tsoelang pele le e tsitsitseng.

Melemo

Ho Kopanya ho Phahameng le ho Kopanya: Li-screws tse peli li fana ka homogenization e ntle haholo, e lumellang ho kopanngoa ha li-polymer le li-additives tse fapaneng.

Phaello e Phahameng le Bokhabane: E fana ka tlhahiso e phahameng le botsitso bo betere ba ts'ebetso ha bo bapisoa le li-scruder tse le 'ngoe.

Ho sebetsana le lintho tse fapaneng: E loketse ho sebetsana le mefuta e mengata ea polasetiki, ho kenyeletsoa PVC, PE, PP, ABS, le lipolasetiki tse tsoakiloeng tse nchafalitsoeng.

Taolo ea Ts'ebetso e Ntlafetseng: Lebelo le ikemetseng la screw le libaka tsa mocheso li lumella phetoho e nepahetseng bakeng sa boleng bo nepahetseng ba pellet.

Degassing e ntlafetseng: Ho tlosoa ka katleho ha mongobo le ho fetoha ha maemo, ho fella ka li-pellets tse hloekileng.

Mefokolo

Matsete a Phahameng a Mathomo: Lits'ebetso tse peli tsa screw hangata li theko e boima ho reka le ho li boloka ho feta li-scruders tse le 'ngoe.

Ts'ebetso e rarahaneng le Tlhokomelo: E hloka basebetsi ba nang le boiphihlelo le tlhokomelo ea kamehla ho boloka li-screw le libarele li le maemong a matle.

Ha e Loke bakeng sa Lisebelisoa tsa Viscosity e Phahameng haholo: Lisebelisoa tse ling tsa viscous haholo li ka hloka lisebelisoa tse khethehileng kapa maemo a ts'ebetso.

Lisebelisoa

Plastic Recycling: E sebetsa hantle bakeng sa ho lokisa litšila tsa polasetiki tse tsoakiloeng hore e be li-granule tse tšoanang hore li sebelisoe hape.

Ho Kopanya le Tlhahiso ea Masterbatch: E sebelisoa haholo ho hlahisa metsoako ea polasetiki e nang le li-filler, li-colorants, kapa li-additives.

PVC le Engineering Plastics Processing: E loketse ho sebetsana le li-polymers tse nang le mocheso le tse rarahaneng.

Tlhahiso e Phahameng ea Ts'ebetso e Phahameng: E sebelisoa ho hlahisa lipolasetiki tse khethehileng tse nang le thepa ea mochine kapa ea lik'hemik'hale.

Lintlha tsa Bohlokoa tsa ho Khetha tse Molemohali Mofuta oa Mochini oa Granulation oa Plastic Recycling

Lintlha tse latelang ke tse ling tsa bohlokoa bakeng sa khetho ea Mochini oa Polastiki ea Recycling Granulation e ka phethahatsang litlhoko tsa hau tsa tlhahiso.

1. Tseba Mofuta oa Hao oa Boitsebiso

Plastiki e Bonolo (mohlala, filimi, mekotla, foam): Khetha mochini o nang le compactor kapa densifier ho netefatsa phepo e ntle.

Lipolasetiki tse thata (mohlala, libotlolo, lijana tse thata): Mohala o pshatlehileng oa granulation o nang le phepo e tsitsitseng o loketse haholoanyane.

Plastiki e Kopantsoeng kapa e Silafetseng: Nahana ka li-scruder tse peli tse nang le matla a ho kopanya le ho sefa.

2. Lekola Litlhoko tsa Bokhoni ba Output

Hakanya bophahamo ba hao ba letsatsi le letsatsi kapa khoeli le khoeli.

Kgetha mmotlolo o tsamaellanang le tlhahiso eo o e batlang (kg/h kapa ditone/letsatsi) ho qoba ho fokotsa boholo kapa ho feta.

Bakeng sa lisebelisoa tse kholo, lisebelisoa tse phahameng tsa twin-screw kapa mekhahlelo e 'meli li loketse.

3. Hlahloba Litlhoko tsa ho Fepa & Pele ho Phekolo

Na thepa ea hau e hloka ho hlatsuoa, ho omisoa kapa ho siloa pele ho granulation?

Mechini e meng e kenyelletsa li-shredders tse kopaneng, li-washer kapa li-compactor. Tse ling li hloka lisebelisoa tsa kantle.

Lisebelisoa tse litšila kapa tse metsi li hloka lisebelisoa tse matla tsa degas le ho qhibiliha ho qhibiliha.

4. Nahana ka Boleng ba ho qetela ba Pellet

Bakeng sa lisebelisoa tsa boemo bo holimo (mohlala, ho foka filimi, ho bopa ka ente), boholo bo sa fetoheng ba pellet le lintho tse hloekileng.

Mechini e nang le taolo e nepahetseng ea mocheso le mochini o fetolang skrineng o iketsang o hlahisa li-granules tse hloekileng, tse tšoanang.

5. Matla a Matla le Boiketsetso

Batla mechini e nang le li-motor tse laoloang ke inverter, liheater tse bolokang matla, le automation ea PLC.

Mekhoa e ikemetseng e fokotsa litšenyehelo tsa basebetsi le ho netefatsa boleng bo tsitsitseng ba tlhahiso.

6. Tlhokomelo & Tšehetso ea Likarolo tsa Spare

Khetha mochini ho tsoa ho morekisi ea tšepahalang o nang le litšebeletso tse arabelang kapele, tšehetso ea tekheniki, le likarolo tse ling tse fumanehang habonolo.

Meetso e bonolo e ka fokotsa nako ea ho theoha le ho fokotsa litšenyehelo tsa nako e telele tsa tlhokomelo.

7. Ho Itloaetsa & Katoloso ea Bokamoso

Nahana ka mechini e nang le meralo ea modular e lumellang lintlafatso (mohlala, ho eketsa extruder ea bobeli kapa ho fetola mofuta oa pelletizing).

Sistimi e feto-fetohang e ikamahanya le mefuta e mecha ea thepa kapa tlhahiso e phahameng ha khoebo ea hau e ntse e hola.

Nahana ka WUHE MACHINERY's Plastic Recycling Granulation Machine Service

Joaloka moetsi ea hloahloa ea nang le boiphihlelo ba lilemo tse fetang 20, WUHE MACHINERY (Zhangjiagang Wuhe Machinery Co., Ltd.) e ipabola ka moralo, tlhahiso, le ts'ebeletso ea lefats'e ea metjhini ea polasetiki ea granulation.

Ka litsamaiso tse fetang 500 tse kentsoeng le lithane tse fetang limilione tse 1 tsa polasetiki tse sebetsoang selemo le selemo-ho fokotsa lithane tse hakanyetsoang tsa 360,000 tsa tlhahiso ea CO₂-WUHE e pakile bokhoni ba eona ba botekgeniki le phello ea tikoloho.

E tšehelitsoe ke litifikeiti tsa ISO 9001 le CE, li fana ka tharollo e kopaneng bakeng sa filimi, mokotla o lohiloeng, EPS/XPS, polasetiki e pshatlehileng, le likhoele tse peli tsa granulation. Taolo ea bona e tiileng ea boleng, moralo oa sistimi e tloaelehileng, ho tenyetseha ha OEM/ODM, le ts'ehetso e arabelang ka mor'a thekiso e netefatsa hore bareki ba B2B ba fumana litharollo tse tšepahalang, tse sebetsang hantle, le tse lokiselitsoeng ho sebelisoa hape lefatšeng ka bophara.

Khetha WUHE MACHINERY bakeng sa ts'ebetso e ka tšeptjoang, litharollo tse hlophisitsoeng tsa ho tsosolosa, le molekane ea tšeptjoang ho aha indasteri ea polasetiki e tala, e tsitsitseng haholoanyane.

Nako ea poso: Jul-01-2025