Plastiki e phahameng ea filler parallel twin screw recycling le mochini oa granulation line

Parameter e kholo

Screw loader

● E lumellana le extruder feeding hopper ho hlokomela taolo ea othomathike.

Ea fepang

● Hopper thepa: Tšepe e sa hloekang; Mokhoa oa ho fepa: Ho fepa ka li-screw; Feeder controller: E laoloa ke inverter.

Mochini oa Extruder

● Sekoti le cylinder li amohela sebopeho sa "building block", se nang le phetoho e ntle 'me se ka sebelisoa ka motsoako ofe kapa ofe ho latela mekhoa e fapaneng ea ho sebetsana le thepa; Silinda e entsoe ka tšepe ea nitrided le lisebelisoa tsa bimetallic, tse sa tsitsang le.

● Ho hanyetsa kutu le bophelo bo atolositsoeng ba tšebeletso; Likarolo tse entsoeng ka likhoele li entsoe ka tšepe ea nitrided le tšepe ea lisebelisoa tsa lebelo le phahameng, 'me li-curve li entsoe ka moralo o thusoang ke k'homphieutha, ho kopantsoe le mekhoa e ikhethang ea ho sebetsa, ho netefatsa meno a tloaelehileng a karolo e sebetsang ea khoele.

● Ho hloekisa holim'a metsi le ho itlhoekisa hantle; Mokhoa o ikhethileng oa ho hokahanya le sesebelisoa sa phetisetso se matlafatsa matla a likarolo tse lohiloeng le li-core shafts, ho fihlela phallo ea thepa e ts'oanang, ho kopanya hantle le phello ea polasetiki, le hysteresis ea lintho tse bonahalang.

● Sepheo sa ho boloka nako e khutšoanyane le bokhoni bo phahameng ba ho fetisa.

Ho fetola skrine

● Liphetoho tse fapaneng tsa skrine li finyella litlhoko tsa bareki ba fapaneng.

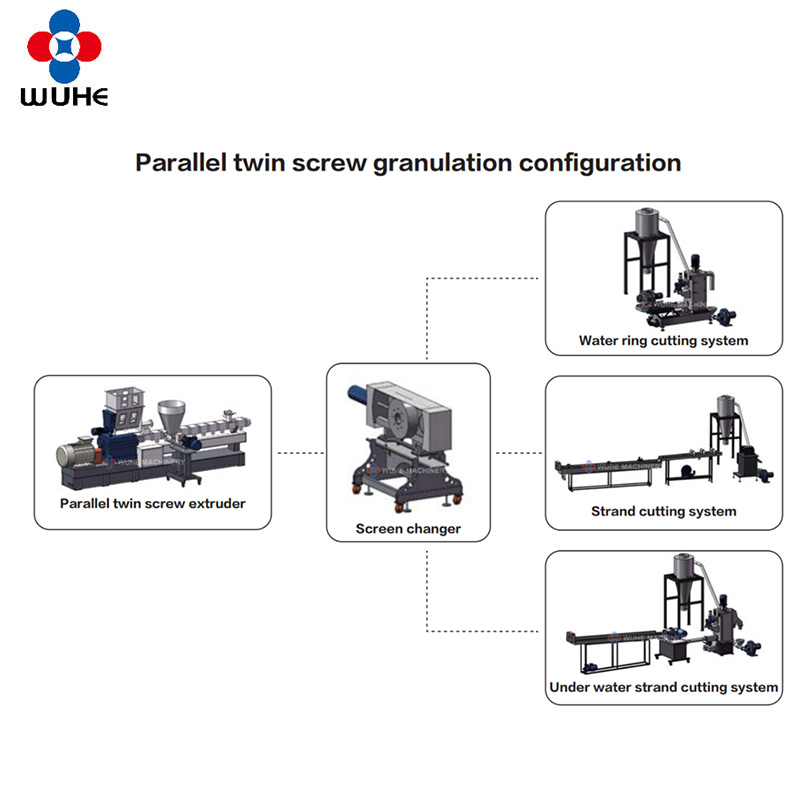

Haholo-holo re na le mekhoa e meraro ea tsamaiso ea ho khaola li-pellets:

1. Mokhoa oa ho itšeha lesale la metsi.

2. The strand cutting system.

3. Mokhoa oa ho itšeha ka tlas'a metsi.

Ho itšetlehile ka litšobotsi tse fapaneng tsa thepa, re tla khothaletsa mekhoa e fapaneng ea ho itšeha.

1. Mokhoa oa ho itšeha oa metsi

● Tsamaiso ea ho itšeha e amohela lesale la metsi a extrusion shoela ho khaola, e ka netefatsang ponahalo e phethahetseng ea karoloana.

Mochine o hlatsoang metsi oa centrifugal

● Mochine ona o na le melemo e mengata, e kang tekanyo e phahameng ea ho felloa ke metsi 'meleng, tšebeliso e tlaase ea matla, bokhoni bo phahameng, tekanyo e phahameng ea ho iketsetsa,' me e fokotsa haholo matla a mosebetsi. Dehydration e hloekile, 'me e ka boela ea hlatsoa lehlabathe le lenyenyane le li-sundries tse nyane ka har'a pla.

2. Strand cutting system

● Bakeng sa lisebelisoa tse ling tse nang le viscosity e phahameng, tse kang PP, re khothalletsa ho sebelisa mokhoa oa ho itšeha.

Sistimi ea ho itšeha ka tlas'a metsi

● E loketse lisebelisoa tse phahameng tse qhibilihisang, tse kang PET le PP joalo-joalo.

● Ho omisa lipeipi tsa moea

Metsi a ka holim'a li-pellets a fetoha mouoane ka mokhoa oa phepelo ea moea, 'me a isa li-pellets tse omisitsoeng ho sekoti sa pokello, ebe bakeng sa kalafo e latelang.

Sistimi ea taolo ea motlakase

● PLC ea ho laola ka mokhoa o itekanetseng

Setšoantšo sa lintho tse bonahalang