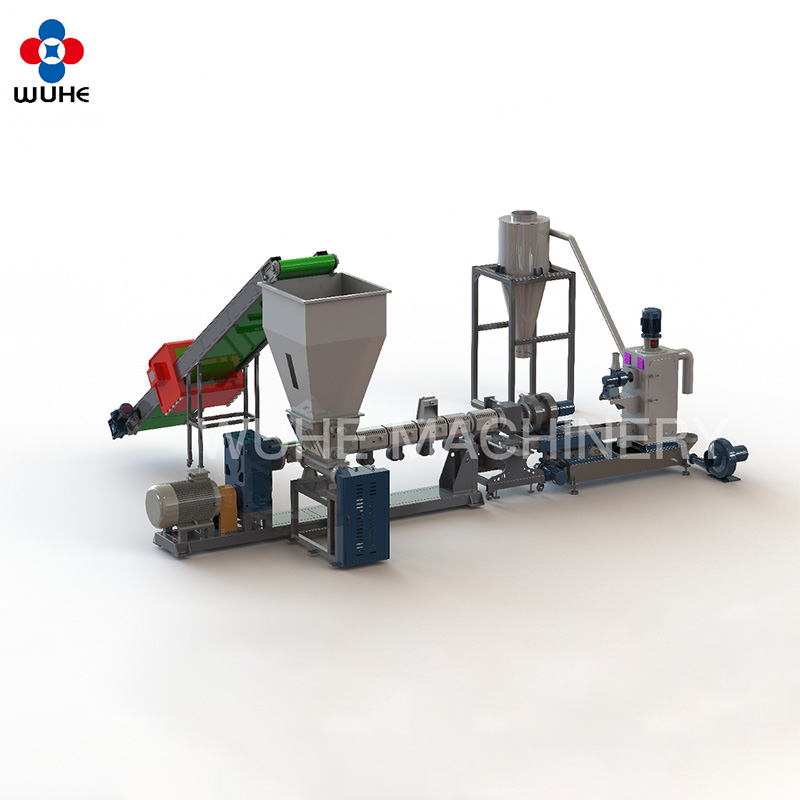

Lisebelisoa tsa foam tsa EPS XPS mochini o le mong oa mekhahlelo e 'meli o ka sebelisoang hape le mochini oa mohala oa granulation

Parameter e kholo

Conveyor+ metal detector

● E tsamaisana le komporo ho hlokomela taolo ea othomathike.

● Metal detector e bohareng ba lebanta, ho lemoha tšepe e tsoang ho thepa, mochine oa China o hlophisitsoeng kapa oa Jeremane.

Lehlakore/Down force/ Ho fepa sehopo

● Ena ke mochine o babatsehang oa ho tsosolosa lisebelisoa tsa foam tse kang EPS le XPS. Haholo-holo re na le mekhoa e 'meli, e' ngoe ke mokhoa oa extrusion oa mahlakoreng, 'me e' ngoe ke mokhoa oa ho fokotsa khatello ea tlaase.

Mochini oa Extruder

● Single screw extruder e nang le moea o phelisang hantle ho ntlafatsa boleng ba lintho tse bonahalang, E na le moralo o khethehileng oa moqomo le sekoti le sistimi e le 'ngoe ea ho khathala, e ka netefatsa chai e ngata.

Sistimi ea ho qeta moea ka vacuum

● Ho ntša moea o sebetsang hantle ho ntlafatsa boleng ba thepa.

● Mokhoa o khathatsang: sefa metsi a vacuum.

● Kamore ea vacuum: moralo o khethehileng.

● Sekoahelo sa vacuum: motsoako oa aluminium.

● Vacuum tube: mocheso le khatello ea khatello ea methapo ea rabara.

Ho fetola skrine

● Liphetoho tse fapaneng tsa skrine li finyella litlhoko tsa bareki ba fapaneng.

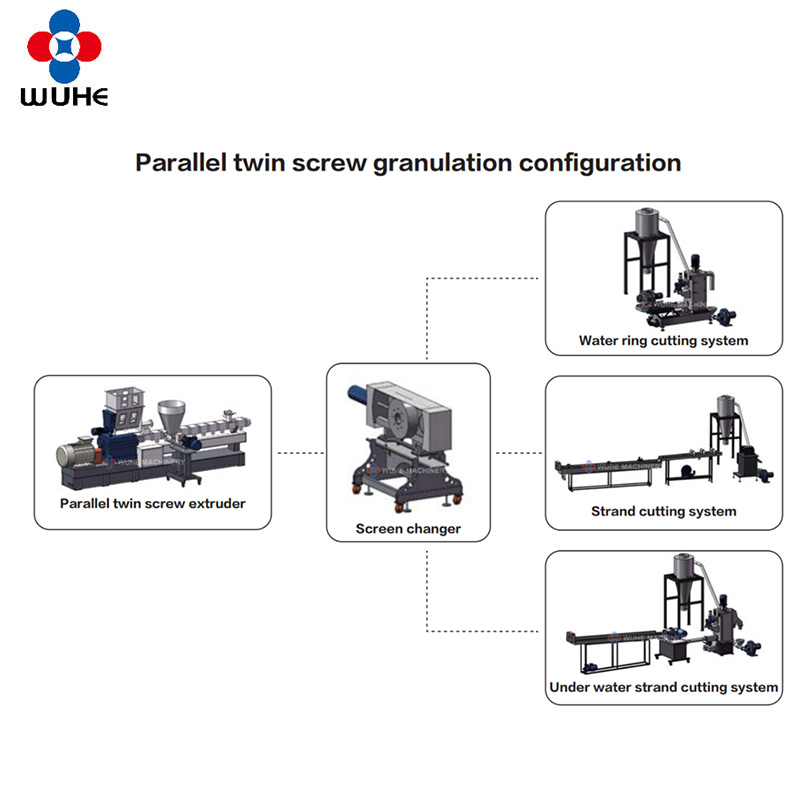

Haholo-holo re na le mekhoa e 'meli ea li-pellets tsa ho itšeha bakeng sa lisebelisoa tsena tsa mofuta:

1. Mokhoa oa ho itšeha lesale la metsi.

2. The strand cutting system.

Ho itšetlehile ka litšobotsi tse fapaneng tsa thepa, re tla khothaletsa mekhoa e fapaneng ea ho itšeha.

1. Mokhoa oa ho itšeha oa metsi

● Tsamaiso ea ho itšeha e amohela lesale la metsi a extrusion shoela ho khaola, e ka netefatsang ponahalo e phethahetseng ea karoloana.

Mochine o hlatsoang metsi oa centrifugal

● Mochine ona o na le melemo e mengata, e kang tekanyo e phahameng ea ho felloa ke metsi 'meleng, tšebeliso e tlaase ea matla, bokhoni bo phahameng, tekanyo e phahameng ea ho iketsetsa,' me e fokotsa haholo matla a mosebetsi. Dehydration e hloekile, 'me e ka boela ea hlatsoa lehlabathe le lenyenyane le li-sundries tse nyane ka har'a pla.

2. Strand cutting system

● Bakeng sa lisebelisoa tse ling tse nang le viscosity e phahameng, tse kang PP, re khothalletsa ho sebelisa mokhoa oa ho itšeha.

● Ho omisa lipeipi tsa moea

Metsi a ka holim'a li-pellets a fetoha mouoane ka mokhoa oa phepelo ea moea, 'me a isa li-pellets tse omisitsoeng ho sekoti sa pokello, ebe bakeng sa kalafo e latelang.

Sistimi ea taolo ea motlakase

● PLC ea ho laola ka mokhoa o itekanetseng

Setšoantšo sa lintho tse bonahalang